Cost may seem the first difference when choosing between Treated and Inherent fabrics for your FR Workwear, but in this post we explain the difference.

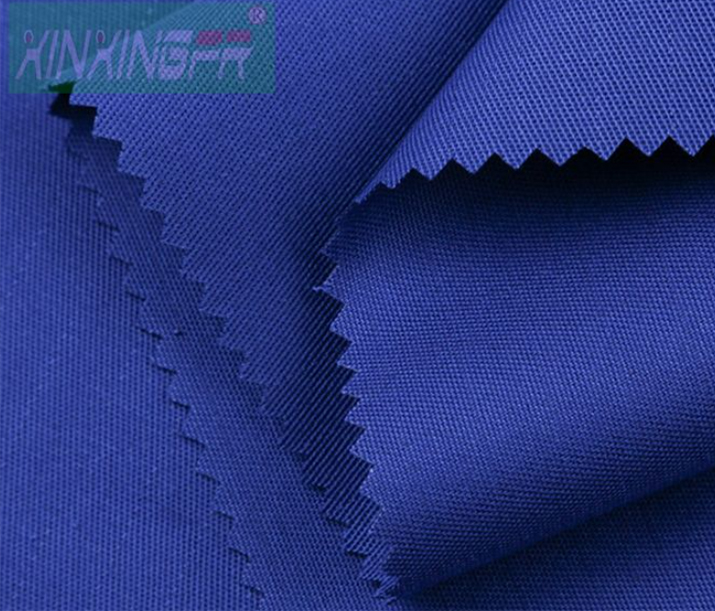

In connection with Flame Resistant (FR) fabrics, the term 'Inherent' is used to describe a fabric whose FR properties are permanent and cannot be removed.

The structure of the fibres used to create the yarns and in turn fabrics are non-flammable and the resulting Inherent Fabric will not burn or melt when exposed to a heat source such as a fire or flame for it's entire lifetime.

When used in Flame Resistant protective clothing, the FR properties can never be washed out or worn away resulting in a garment that guarantees your ongoing protection and long life spans for reduced cost-in-use.

Inherent fabrics are often either Modacrylic or Aramid.

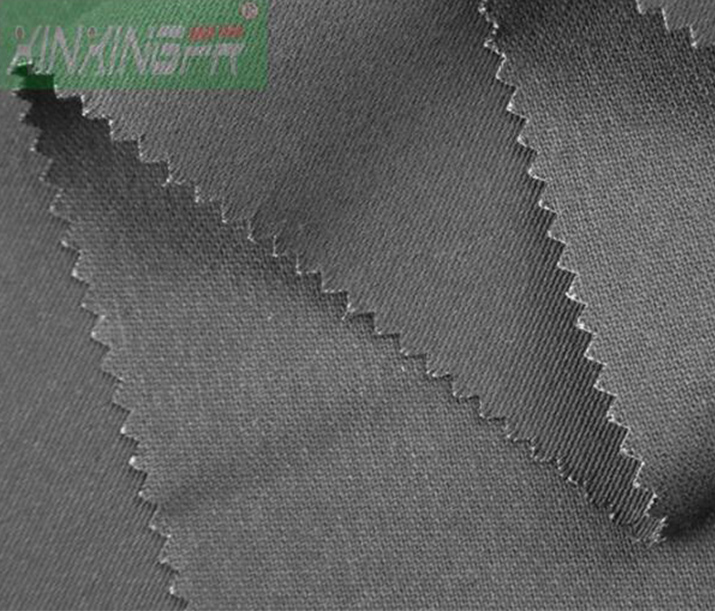

A Flame Resistant (FR) fabric that we refer to as being 'Treated' is a fabric that has been chemically treated to give it its flame resistant properties.

Unlike 'Inherent' fabrics, the properties of these fabrics can be washed out during the garment's lifetime and can therefore be considered a risk to some organizations where safety is paramount.

The EN certification of Treated fabrics can be just the same as Inherent fabrics and can include IEC 61482 Protective Clothing against the Thermal Hazards of an Electric Arc or EN ISO 11612 Heat & Flame Protective Clothing.

The number of washes that Treated fabrics are generally tested to a point where they maintain their FR properties is typically 50 washes.

Inherent Fabrics

Because the flame resistant properties in these fabrics are permanent, they cannot be washed out or removed from the garment, damaged under exposure to chemicals in your workplace, or by the laundering process. This results in a garment that as an employer, you can rely on knowing will always protect your member of staff.

Treated Fabrics

These fabrics may be damaged by the exposure to hazardous chemicals, some chemicals used in the laundering process, or the general washing process itself. As a result, the older the garment becomes, the less protection it potentially provides which cannot always be established from the garments visual appearance. Although some premium brands do offer certification test data for 50 or even 100 Industrial wash cycles, research has shown that after just 10 washes the Flame Resistant properties can be reduced to zero. Considering that some of these fabrics are 99% Cotton/1% Antistatic blends, the result could be that a worker requiring heat and flame protection is wearing an unprotected garment…

Note: You should also remember that a build up of dirt and grease on any FR garment, Inherent or Treated, should be avoided and garments should be washed on a regular basis. We are an FR fabric supplier. If you are interested in our products, please contact us now!

+86 135 9869 3034 (Ada)

South Fenghua Road, High-Tech Industrial Development of Xinxiang, Henan PC, China.

Copyright © Xinxiang Xinxing Special Fabric Co., Ltd. All Rights Reserved. Sitemap | Powered by

SEOKeywords: Custom Flame Resistant Fabrics Flame Resistant Fabrics Application Flame Retardant Knitted Fabrics & Fleece 2024 Flame Resistant Knitted Fabric Fire Retardant High Visibility Workwear Fire-Resistant Fabrics: Understanding Fire Retardant vs. Fire Resistant Fire-Resistant Fabrics: Understanding Fire Retardant vs. Fire Resistant Fire-Resistant Fabrics: Understanding Fire Retardant vs. Fire Resistant